K9

- Features

- Dimensions

- Options

- Accessories

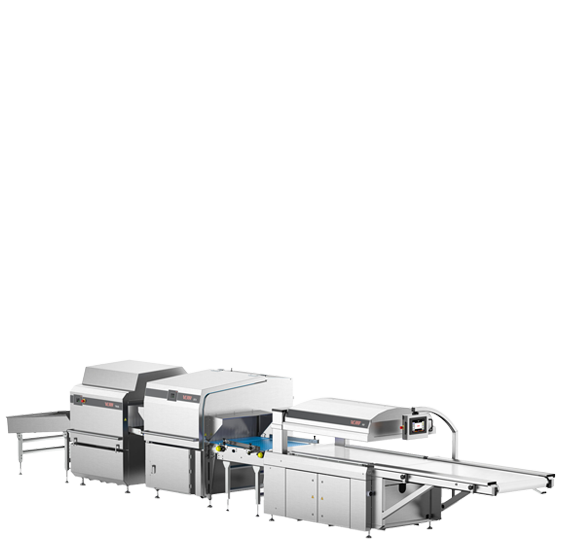

The GIANT of vacuum chamber machines

VC999 complements the range of vacuum packaging chamber machines for the industrial packaging following the VC999 K7 and VC999 K8 with the new VC999 K9, the largest VC999 chamber belt machine so far.

The remarkable dimensions and the innovative technology meet all requirements of large industrial packaging.

The VC999 K9 vacuum chamber belt machine offers the ideal solution for the packing of large products and packaging volumes for the food as well as the nonfood industry.

Compact and hygienic

- Compact design, requires only 5m2 space despite the considerable dimensions.

- All-enclosed design is ideal for industrial requirements.

- Easy-to-clean all stainless construction.

- Meets the strictest hygiene regulations, design based on standard DIN EN 1672-2

- No sharp edges or corners

Functional design

- Simple programming with menu guidance.

- Functional design, ergonomic work surfaces

- Easy access for maintenance

- Variable height adjusting lid design and adjustable chamber volume.

- VFD controlled belt speed assures smooth conveyor movements with quick-release for easy cleaning

- Shrink tank and dryer can be added.

Perfect sealing

- Unparalleled VC999 Vacuum technology (99,9% Vacuum)

- VC999 evacuation stops at the evaporation point for perfect packaging quality.

- Bi-active (from the top and bottom) sealing bars with electronic temperature control and precisely controlled contact pressure.

- Quick and safe sealing even with thick creases, grease or product liquids.

- Leaker rates tending to zero.

- Four sealing heights can be set.

- High-quality sealing of all available sealable materials

User friendly

- 10.4” color touchscreen display.

- Simple to control and program via softkeys.

- Tried and tested settings can be saved – practically eliminating errors.

- Different user levels.

- Various languages can be selected.

- Remote maintenance possible via standard interfaces*

- Can be operated from both sides.

*depends on customer’s infrastructure

Specifications

| Model | VC999 K9 |

|---|---|

| Sealing Bars | |

| Length | 2 x 1500 mm |

| Useable spacing between sealing bars | 894 mm |

| Useable spacing with only one sealing bar used | 940 mm |

| Height adjustment range | 20 mm / 60 mm / 100 mm / 140 mm |

| Max. product height (standard) | 285 mm |

| Height adjusting lid | steps of 20mm up to 300mm, min. 40mm |

| Capacity (cycles/min) | up to 4 |

| Weight without pumps and waste evacuation | approx. 1400kg |

| Power consumption (at 400 V / 3 / 50 Hz) | |

| VC999 K9 without pump | 13 kW / 40 AT |

| Various combinations of pumps possible | |

| Power supply | 440 V / 3 / 50 Hz |

| Other power supplies available on request. | |

| Compressed air connection | 5.5 bar |

| Compressed air consumption per cycle | 45 NI |

- Features

- Dimensions

- Options

- Accessories

The GIANT of vacuum chamber machines

VC999 complements the range of vacuum packaging chamber machines for the industrial packaging following the VC999 K7 and VC999 K8 with the new VC999 K9, the largest VC999 chamber belt machine so far.

The remarkable dimensions and the innovative technology meet all requirements of large industrial packaging.

The VC999 K9 vacuum chamber belt machine offers the ideal solution for the packing of large products and packaging volumes for the food as well as the nonfood industry.

Compact and hygienic

- Compact design, requires only 5m2 space despite the considerable dimensions.

- All-enclosed design is ideal for industrial requirements.

- Easy-to-clean all stainless construction.

- Meets the strictest hygiene regulations, design based on standard DIN EN 1672-2

- No sharp edges or corners

Functional design

- Simple programming with menu guidance.

- Functional design, ergonomic work surfaces

- Easy access for maintenance

- Variable height adjusting lid design and adjustable chamber volume.

- VFD controlled belt speed assures smooth conveyor movements with quick-release for easy cleaning

- Shrink tank and dryer can be added.

Perfect sealing

- Unparalleled VC999 Vacuum technology (99,9% Vacuum)

- VC999 evacuation stops at the evaporation point for perfect packaging quality.

- Bi-active (from the top and bottom) sealing bars with electronic temperature control and precisely controlled contact pressure.

- Quick and safe sealing even with thick creases, grease or product liquids.

- Leaker rates tending to zero.

- Four sealing heights can be set.

- High-quality sealing of all available sealable materials

User friendly

- 10.4” color touchscreen display.

- Simple to control and program via softkeys.

- Tried and tested settings can be saved – practically eliminating errors.

- Different user levels.

- Various languages can be selected.

- Remote maintenance possible via standard interfaces*

- Can be operated from both sides.

*depends on customer’s infrastructure

Specifications

| Model | VC999 K9 |

|---|---|

| Sealing Bars | |

| Length | 2 x 1500 mm |

| Useable spacing between sealing bars | 894 mm |

| Useable spacing with only one sealing bar used | 940 mm |

| Height adjustment range | 20 mm / 60 mm / 100 mm / 140 mm |

| Max. product height (standard) | 285 mm |

| Height adjusting lid | steps of 20mm up to 300mm, min. 40mm |

| Capacity (cycles/min) | up to 4 |

| Weight without pumps and waste evacuation | approx. 1400kg |

| Power consumption (at 400 V / 3 / 50 Hz) | |

| VC999 K9 without pump | 13 kW / 40 AT |

| Various combinations of pumps possible | |

| Power supply | 440 V / 3 / 50 Hz |

| Other power supplies available on request. | |

| Compressed air connection | 5.5 bar |

| Compressed air consumption per cycle | 45 NI |

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec quis massa condimentum, viverra tortor nec, sagittis neque. Nunc pharetra efficitur nibh, a pretium nibh viverra vitae.

Peter White

Store manager